Engine Cooling System

Importance:

At the time of firing, the combustion temperature rises up to 1200°C in the petrol engine and 2000°C in a diesel engine. The melting points of cast iron, steel, and aluminum alloys are 1100°C, 1450°C, and 660°C respectively. In this situation above the cooling is very essential and very important to protect engine components from overheating and melting-

Functions:

- temperature is 75° to 85°c.

- Protects engines from overheating.

Methods of Cooling:

Air cooling system:

Normally used for small engines. The cylinder finis helps to cool the engines through radiation by leaving heat in the atmosphere. These fins actually increase the cross-sectional area where the heat spread nut towards the outer edges of the fins. Then atmospheric air absorbs heat through radiation that results in the cooling of engines. This system is used in motorcycle/bike engines, baby taxis, and some portable power sprayer engines.

Water cooling system:

a) Hopper cooling:

The water jacket around the cylinder where water moves around, which absorbs heat and keeps cool the engine.

An open water tank is constructed over water jacket where water is getting hot and lighter through convection, then this water goes up and the less hot and cool water comes down to fill that place. By running out of the water through evaporation and finally the addition of fresh cool water in the tank, thus and these ways the system works continuously in the engine. It was used in the steam engine, now it is an old and backdated system not in use more these days.

b) Thermo syphon system of Cooling:

The radiator, header tank and bottom tank of the radiator, water tubes in radiator, upper and bottom hose pipes of radiator linked with the engine, mechanically engine-driven fan, water jacket exists around engine cylinders and the temperature gauge is participating altogether with the created thermo-symphonic stream or flow within the system.

The water around the cylinders absorbs heat and becomes hot and lighter that goes up and enters to the header tank and water tubes in the radiator. The engine-driven fan draws air from outside through the gaps of water tubes that absorb heat by cooling water in the tubes.

The water in the tubes become heavier and comes down to fill up the place of hot water that goes up to the header tank. This way the system works and creates a thermo-symphonic flow in the system. A cold or overheated engine cannot work properly, the cooling water should be at a temperature of approximately 90°cj to ensure efficient operation. Keep an eye on the temperature gauge on the instrument panel.

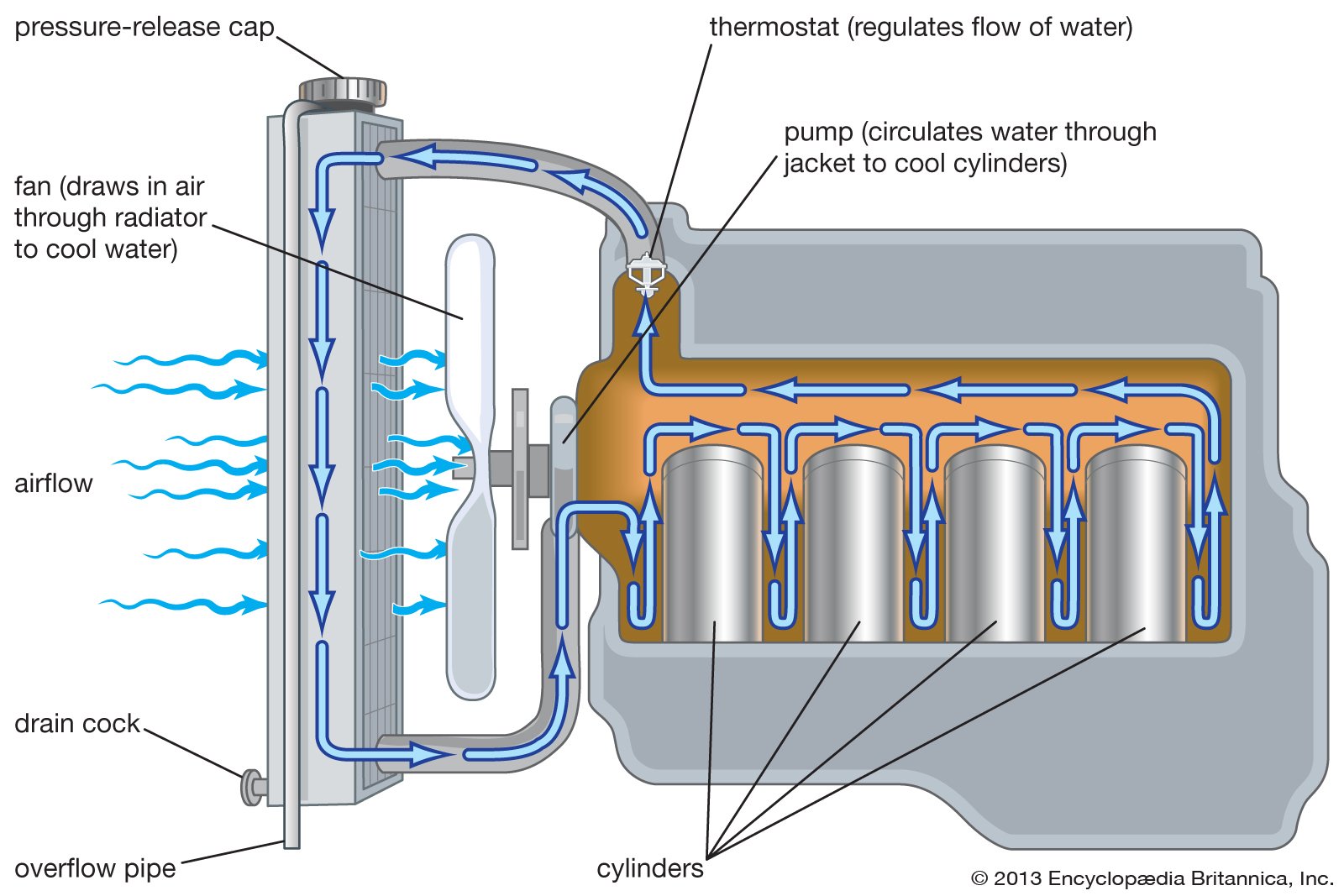

c) The forced circulation system of Cooling:

In this system the above addition of that there is a pump land thermostat valves are placed at their required positions. The pump works in the water jacket of the engine and the thermostat valve is fixed and connected to the upper hose pipe of the radiator; that works at the temperature range of 74 c 10 80 c.

The water at the water jacket absorbs heat from the combustion chamber of engine cylinders raises the water temperature up and getting hot and lighter weight. This water temperature helps to open the thermostat valve which allows water to pass into the radiator.

Radiator:

A radiator is constructed to provide the largest possible area ‘of surface that can be exposed to fan-assisted airflow. A radiator is made up of a header tank and a bottom tank which are connected together by a lot of thin tubes through which the water flows. The tubes are also in contact with numerous thin metal plates and this provides a further increase in surface area. The whole radiator looks like a honeycomb through which air can flow, behind the radiator.

A Thermostat valve:

An additional device usually fitted into the cooling system is a thermostat. This is used to help control the temperature of the water in the vicinity of the cylinders. It is very useful when an engine is started up from cold or when it has to “idle” (run slowly) for a long time.

A thermostat is a form of automatic valve fitted into the outlet pipe connecting the cylinder head to the top of the radiator. It restricts the flow of water to the radiator until an efficient working temperature is reached within the cylinder block.

The flow of water is either stopped, has limited movement, or unrestricted movement according to the temperature of the water. Because the volume of water within the cylinder block is much less than that within the whole cooling system, it means that rapid warming up from cold takes place.

The water in the block is circulated by the water pump while the thermostat is closed; a by-pass is incorporated in the circuit to allow this internal circulation. The thermostat valve may also be a bi-metallic strip type and the above one is called a bellows type. The suitable working temperature of an engine is about 90°C (194°F) and this should be maintained if possible.

The Pump:

Thermo-siphon circulation by itself is not satisfactory for the modern engine; the movement of the water is usually helped by an impeller. This impeller is a metal disc with vanes around one of its faces. It is positioned in the cooling system and driven by the fan shaft. As it rotates it draws cooler water up from the bottom of the radiator, thus helping circulation.

Frost Protection in water cooling:

A water-cooled engine that has to stand or operate in temperatures of freezing point and below must have a property of anti-freeze solution mixed with the water. This will prevent damage to the radiator and engine. When water freezes it expands with a considerable force, fully capable of fracturing cast-iron cylinder blocks, cylinder heads, or radiators.

An antifreeze solution, ethylene glycol is used to protect the cooling system from frost damage. A 25 percent solution of antifreeze and water will protect the system that lowers down to a temperature of about -18°c (0° F) A 25 percent solution consists of two Liters of antifreeze with six liters of water. Antifreeze does not prevent freezing, it only lowers the freezing points of the coolant. It lowers the boiling points too. It is best to top up the cooling system with a ready-mixed antifreeze solution during the winter months.